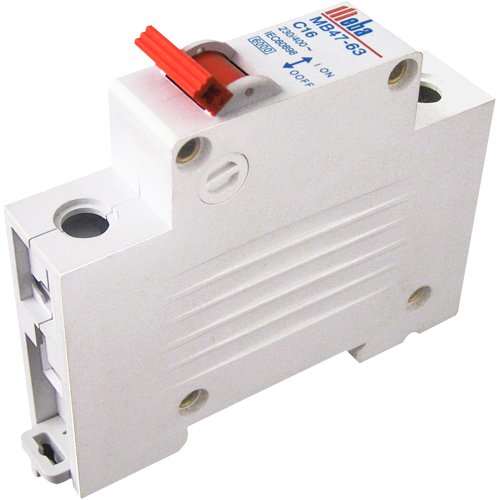

When it senses an over current or a short circuit, an ac breaker instantly shuts off an electrical circuit. When a circuit’s current flow exceeds its rated capacity, over current develops, which increases the danger of overheating and electrical fires. When two conductors with differing potentials come into contact, a short circuit occurs instead, providing a low-resistance channel for the current to pass.

When it senses an over current or a short circuit, an AC breaker is made to stop the flow of current. It comprises a switch that automatically flips open when the current reaches a certain threshold, breaking the circuit and stopping further harm to the wire and equipment.

What Functions of an AC Breaker?

An electrical panel or distribution board is normally where an AC breaker is located, acting as the first line of defense against over current and short circuits. The switch opens and the circuit is broken when the internal mechanism of the breaker is activated, which happens when the current flowing through the circuit exceeds the rated capacity of the breaker.

An electromagnet and a bimetallic strip normally make up the internal mechanism of an AC breaker. The switch is connected to the electromagnet, which is powered by the circuit’s current flow. The electromagnet produces a magnetic field that pulls the switch, opening it and breaking the circuit when the current exceeds the breaker’s rated capacity.

The bimetallic strip, on the other hand, is composed of two metals with differing thermal expansion coefficients. The bimetallic strip warms up and bends when the circuit’s current exceeds the rated capacity of the dc breaker, tripping the switch and cutting the circuit.

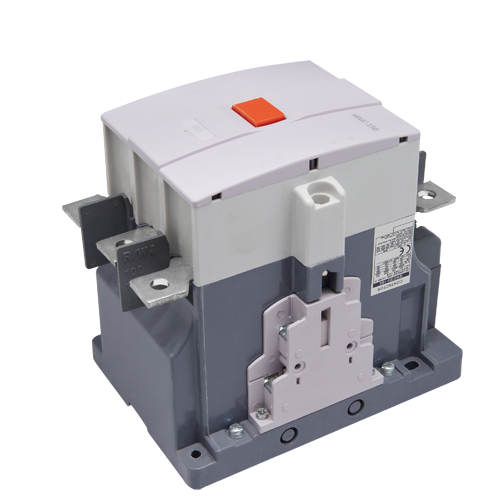

Why Are Breakers For AC Required?

Because they offer protection against over current and short circuits, AC breakers are crucial parts of any electrical system. In the absence of a breaker, an over current or short circuit might overheat the wire and the apparatus, posing a risk of electrical fires and other dangers.

Additionally, AC breakers are made to trip promptly in the case of an over current or short circuit, minimizing harm to the wiring and equipment. This lowers the cost of repairs and guarantees that the electrical system is operational as soon as feasible. In conclusion, air circuit breaker and AC breakers are essential parts of every electrical system because they guard against short circuits and over current.

When they notice an over current or short circuit, they instantly cut the power, protecting the wires and the device. To protect the safety of your equipment and the people using it, it is important to make sure that your electrical system is equipped with the proper type and rating of AC breakers.

Follow us on Twitter