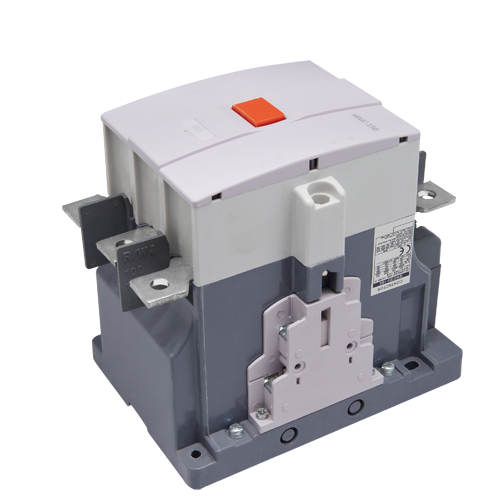

An electrical device called an electric contactor is used to turn on or off electrical circuits. It is thought of as a special form of a relay. Applications requiring a higher current carrying capacity are used contactors, and those requiring a lower current are used relays. This is the key difference between a contactor and a relay. Contactors are compact and easily installed in the field. These electrical devices often have many contacts. When the contactor coil is activated, these contacts—which are often ordinarily open—provide operational power to the load. Electric motor control frequently involves the use of contactors.

There are several kinds of contactors, and each kind has a unique set of characteristics, uses, and applications. Many different currents and voltages, ranging from a few amperes to hundreds of amperes and thousands of volts, can be broken by contactors. These electrical gadgets also exist in a variety of sizes, from those that can be handled in the hand to those that measure a meter or yard on one side.

High-current loads are the contactor’s most typical application area. The capacity of contactors to manage currents of more than 5000 amperes and high power greater than 100 kW is well recognized. Arcs are created when heavy motor currents are interrupted. A magnetic contactor can be used to decrease and manage these arcs.

Contactor Substitutes

Three of the contactor’s essential parts are as follows:

Coil versus magnet: This is the part of a contactor that is most important. The coil or electromagnet of the contactor supplies the driving power needed to shut the connections. An enclosure serves as protection for the contacts and coil of the electromagnet.

Enclosure: Just as in any other application, contactors have an enclosure that serves as insulation and a barrier between people and the contacts. Different materials, including polycarbonate, polyester, Nylon 6, Bakelite, thermosetting polymers, and others, are used to create the protective casing. The open-frame contactor typically has an extra enclosure that shields it from inclement weather, explosion risks, dust, and oil.

Contacts: This electrical device’s contacts are yet another crucial part. The contacts handle the contactor’s duty of transporting current. An electrical contactor has three different types of connections: power contacts, auxiliary contacts, and contact springs. Every form of touch has a certain function to fulfill.

Follow us on Facebook