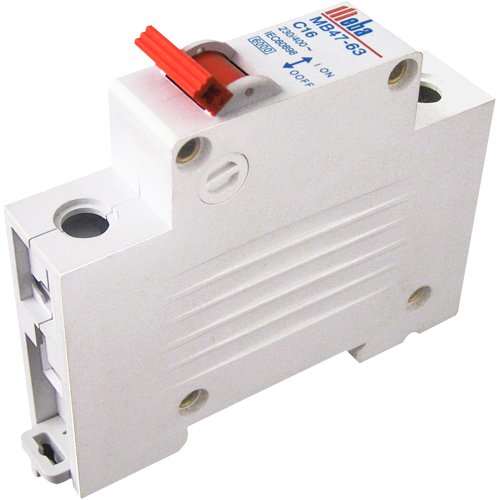

A circuit breaker is a crucial electrical component designed to protect electrical circuits from damage caused by excess current. It functions as an automatic switch that interrupts the flow of electricity when it detects a fault, such as overloading or short circuits. Here’s a breakdown of how circuit breakers work and their key components:

Function: The primary function of a circuit breaker is to prevent damage to electrical circuits and appliances by interrupting the flow of electricity when abnormal conditions occur. This could include overcurrent situations, such as when too many devices are connected to a circuit or when a short circuit occurs.

Operation: When normal current flows through a circuit, the circuit breaker manufacturer remains closed, allowing electricity to pass through uninterrupted. However, if the current exceeds a predetermined threshold (the rated current), the circuit breaker will trip, opening the circuit and stopping the flow of electricity.

Types: Circuit breakers come in various types, including:

Thermal Circuit Breakers: Operate based on the heat generated by excessive current.

Magnetic Circuit Breakers: Operate based on the magnetic field generated by excessive current.

Thermal-Magnetic Circuit Breakers: Combine both thermal and magnetic mechanisms for enhanced protection.

Electronic Circuit Breakers: Use electronic components to monitor and control current flow.

Applications: Circuit breaker manufacturer are used in residential, commercial, and industrial electrical systems to protect circuits, wiring, and electrical devices from damage due to over current conditions. They are installed in distribution panels, circuit breaker boxes, and electrical appliances.

Overall, circuit breakers play a critical role in electrical safety by protecting against potential hazards and ensuring the reliable operation of electrical systems.