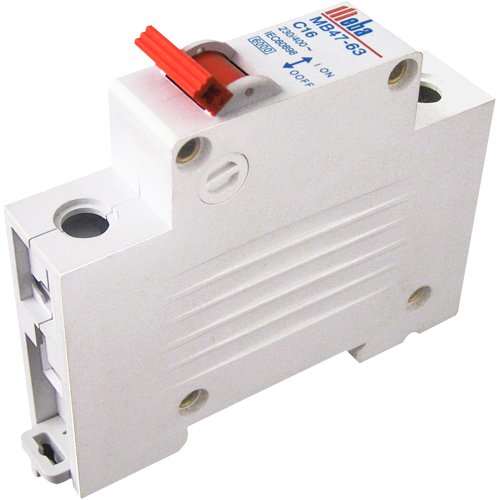

A circuit breaker primary function is to automatically shut an electrical circuit off when it receives too much current. Simply put, it serves as a guardian who keeps an eye on and controls the flow of energy inside a circuit. The circuit breaker quickly shuts the electrical flow when it detects an excessive spike in current, avoiding possible risks including electrical fires and equipment damage.

Functions of a Circuit Breaker

The principles of electromagnetism and thermal-magnetic tripping govern how circuit breakers work. An electromagnet and a bimetallic strip are two crucial parts that are located inside the breaker. The electromagnet and the bimetallic strip cooperate to keep the circuit closed under typical working circumstances, enabling current to flow freely.

The current, however, is more than the breaker’s rated capacity when there is an overload or short circuit in the circuit. The high current at this location causes the bimetallic strip to heat up quickly, bend, and engage the tripping mechanism. The electromagnet detects the irregular current concurrently and produces a magnetic field that helps trip the vacuum circuit breaker open.

Circuit Breaker Types

Circuit breakers that use heat: These are frequently employed in domestic and light business settings. These breakers’ bimetallic strips react to the heat from an excessive current by tripping the circuit.

Industrial settings often have magnetic circuit breakers, which employ an electromagnet to detect a rapid rise in current and trip the circuit.

Circuit breakers that combine magnetic and thermal properties are known as thermal-magnetic circuit breakers, and they may be used in a variety of applications.

Circuit breakers’ importance in preventing fires: To avoid electrical fires, circuit breakers are essential. They protect electrical systems and the surrounding area by swiftly stopping the flow of electricity during an overload or short circuit.

Equipment protection: Excessive current can harm expensive and delicate electrical devices like computers and appliances. Circuit breakers protect such equipment from potential danger by acting as a shield.

Electrical System Safety: By isolating malfunctioning circuits, they guard against electric shocks and other electrical dangers.

Avoiding Power Outages: Earth leakage circuit breaker ensure a more dependable power supply by immediately identifying and isolating faults, which helps prevent widespread power outages.