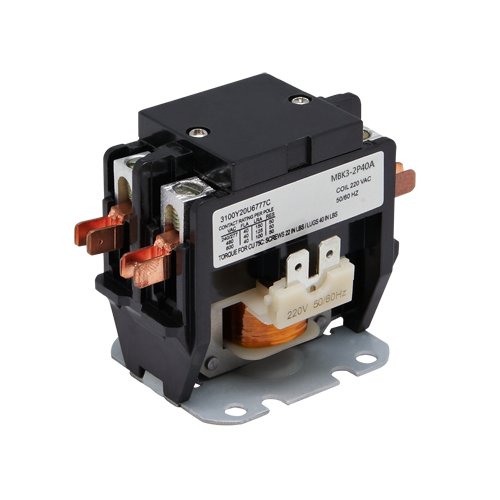

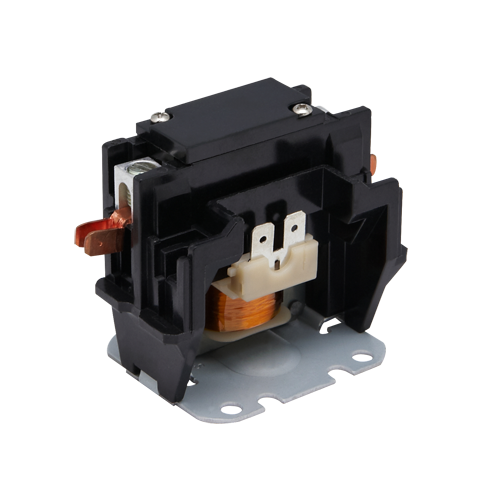

Electric motors, lights, heaters, and other electrical loads are all managed by electrical contactor, which are electromechanical switches. They are made up of a series of contacts that may be opened or closed to let or prevent the passage of electricity. Usually, these connections are composed of durable, highly conductive materials like silver.

An electromagnetic coil must receive an electrical signal for electrical contactors to function. The contacts shut as electricity passes through the coil because it creates a magnetic field that draws an armature. On the other hand, the contacts open because of spring tension or other processes when the current is cut off and the magnetic field decreases.

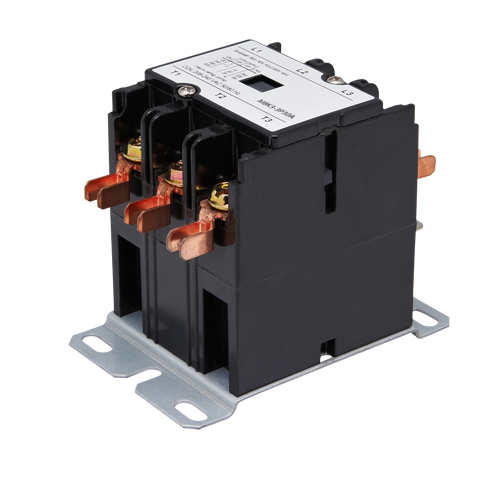

Comprehending Magnetic Contactors

Conversely, magnetic contactors don’t require an outside electrical signal to work; instead, they rely only on magnetic force. They are frequently utilized in settings like heavy-duty industrial machines where a great degree of dependability and safety are necessary.

Magnetic contactors, like electrical contactors, are made out of contacts that may open and close to regulate electrical circuits. However, magnetic contactors employ an electromagnet or permanent magnet that is activated by the current passing through the contacts itself to actuate the contacts rather than depending on an electromagnetic coil. As a result, the contacts in this self-sustaining system stay closed as long as the current is passing through the circuit.

Principal Distinctions and Uses

How electrical and magnetic contactors operate is the main distinction between them. Whereas magnetic contactors are self-actuating and do not require an external signal once activated, electrical contactors need an external electrical signal to actuate the contacts.

Electrical contactor applications:

Air conditioning

Controlled lighting

Automation in industry

Motor control in buildings, both residential and commercial

Uses for Magnetic Contactors

Large machinery and apparatus

Scramblers and elevators

Systems for distributing power

Big industrial motors

Benefits and Things to Think About

Every kind of contactor has its own set of benefits and things to think about.

Electric contactor: Adaptable control choices that accept signals from outside sources.

Appropriate for a large number of uses.

Relays and other extra parts could be needed for intricate control systems.

Magnetic contactors: Dependence on outside signals is decreased by self-sustaining functioning.

High durability and dependability, particularly under challenging conditions

May have a higher initial cost than electrical contractors